A team of researchers from Swansea University has successfully 3D-printed a coral-inspired bone graft. This breakthrough innovation introduces a game-changing material that naturally dissolves in the body after the grafting process and accelerates healing.

Tackling Bone Defects and Disabilities

Bone defects caused by fractures, tumors, or unhealed injuries are among the leading causes of disability worldwide. While bone tissue can regenerate naturally, factors like aging, disease, or the severity of defects can slow the process. For larger defects, scaffolds or bone grafts are often necessary to support regeneration.

Traditionally, autografts (from the patient) and allografts (from donors) have been used to address such issues. However, these methods face challenges like limited availability, infection risks, and ethical concerns. Synthetic bone grafts offer an alternative, but they often fall short in terms of performance, integration, and degradation time. The new material developed by Swansea researchers mimics natural bone in structure and biological behavior, offering a solution to these challenges.

Why Coral?

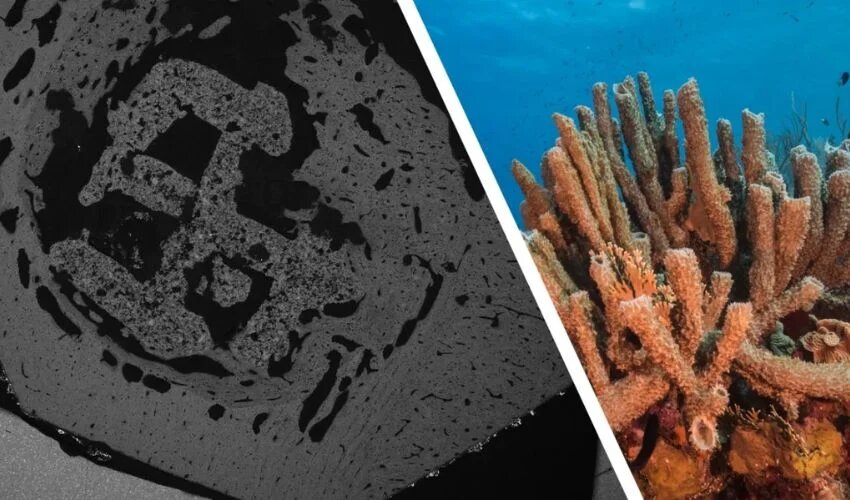

Coral has long been studied as a potential bone graft substitute. Since the 1970s, researchers have found that certain corals resemble spongy bone in mechanical properties and biocompatibility. Coral’s porous calcium carbonate structure is recognized as a clinically useful bone graft material.

Building on this legacy, the Swansea team designed a new material replicating coral’s porous structure and chemical composition. Using Envisiontec’s 3D Bioplotter or casting and drying techniques, they fabricated this innovative graft.

Promising Preclinical Results

Preclinical in vivo trials on rats and miniature pigs revealed impressive results: the graft fully repaired bone defects within three to six months. In just four weeks, it also stimulated the formation of a healthy cortical bone layer.

A Revolutionary Material

This 3D-printed bone graft offers numerous advantages:

- Accelerated healing: New bone growth occurs within 2–4 weeks.

- Natural biodegradation: The material dissolves within 6–12 months, leaving behind only healthy bone.

- Scalability: Unlike natural coral or donor bones, it can be mass-produced with ease.

Dr. Zhidao Xia from Swansea University’s Medical School, who led the research in collaboration with scientists and engineers, highlighted the transformative potential of this invention:

- « Our innovation bridges the gap between synthetic substitutes and donor bones. We’ve proven that it’s possible to create a safe, effective, and scalable material to meet global demand. This could eliminate reliance on donor bones and resolve ethical and supply challenges in bone grafting. »

A New Horizon for Biomedical Applications

By addressing supply chain and ethical concerns, this graft could significantly reduce healthcare costs and improve patients’ quality of life. Swansea University is now seeking partnerships with businesses and healthcare organizations to make this technology widely available.

What’s your take on this 3D-printed bone graft? Share your thoughts in the comments below! For more updates, follow us on YouTube or LinkedIn.

Photo Credits:

- Left: 3D-printed material implanted in vivo for 4 weeks, captured using a scanning electron microscope (credit: Dr. Zhidao Xia).

- Right: Coral image (credit: Jesus Cobaleda).

Source: 3dnatives